|

|

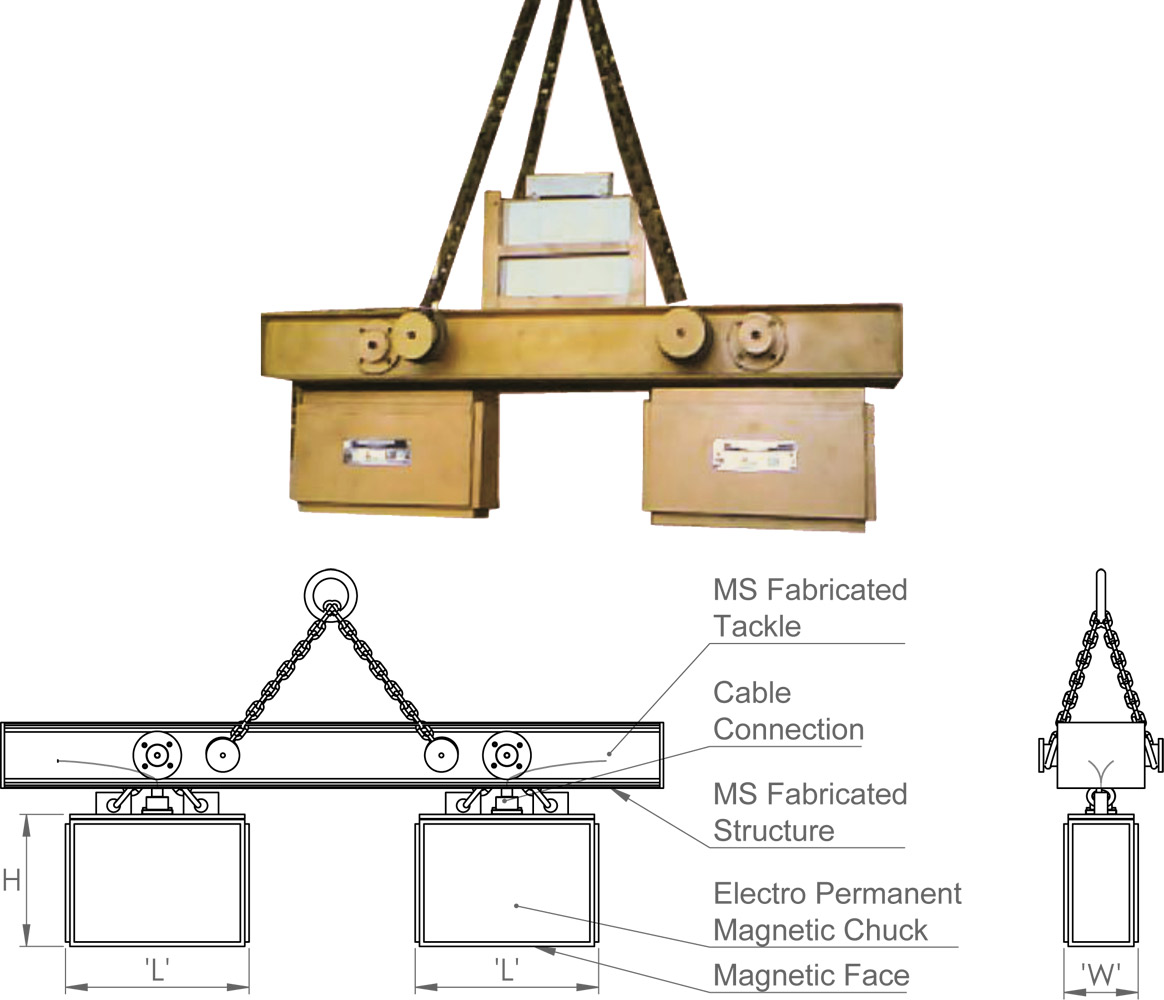

We are Manufacturer, Supplier, Exporter of Electro Permanent Magnetic Lifters and our setup is situated in Pune, Maharashtra, India.

Application

Electro Permanent Magnetic Lifter is device, require for easily handling

of material so that laborious & time consuming work can be avoid in addition to that those material not having any provision for engaging the crane hook or any similar

arrangement Magnetic lifter is solution for it. Hence it increases efficiency and productivity.

Characteristics

A special feature of this kind of lifter is its required External Power

supply for energized and De-energized (ON -OFF) purpose only, during

the operation continues power supply is not required absolutely.

Performance of Lifter

Consider 40% lifting force while lifting round job due to it line contact. For 100% utilization of recommended capacity, required close contact

between magnetic face and lifting object.

Safety Factors

We provide three times factor of safety in it, which means, if lifter is

recommended for 100 Kgs weight lifting capacity, it has been tested for

300 kgs lifting capacity, because practically magnetic face is not cover

100% with lifting object due to its unevenness, scaling, some coating

on the job punching some character or number etc. these all factors are

creating GAP between magnetic face and lifting object, hence factor of

safety should be considered.

Operation Sequence (Follow-up the steps)

Scope of supply

Accessories

Precautions

Available Sizes

| Code No. | Size (Lx WxH) | Lifting Capacity | Self Wt. (Approx.) |

| 013-01-01 | 350 x 100 x 110 mm | 300 Kgs | 30 Kgs |

| 013-01-02 | 405 x 230 x 80 mm | 600 Kgs | 60 Kgs. |

| 012-01-03 | 465 x 175 x 220 mm | 1000 Kgs | 150 Kgs. |