|

|

We are Manufacturer, Supplier, Exporter of Single Coil Electromagnetic Chucks and our setup is situated in Pune, Maharashtra, India.

Application

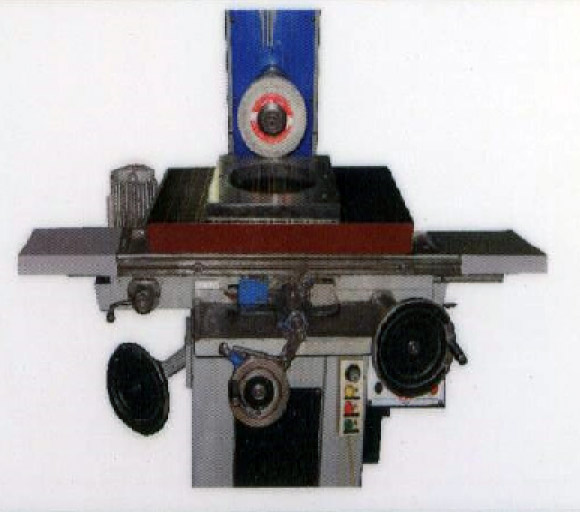

Electromagnetic Chucks are designed for GRINDING operations. It

generates strong magnetic force to hold work piece in rigid manner.

These chucks are operated on continues D.C. Power Supply. There is

no internal wear and deformation corresponding to movement of internal

parts, which provides a better life than conventional Permanent Magnetic

Chuck.

Characteristics of Electromagnetic Chuck

Characteristics of Control Panel

Inspection

Following tests are applied to inspect a chuck:-

| Model Code | Size ( L x W x H ) | Pole Gap | Pole Pitch |

| 002-01-01 | 450 x 150 x 100mm | 15mm | 40mm |

| 002-01-02 | 500 x 200 x 100mm | 15mm | 40mm |

| 002-01-03 | 600 x 200 x 100mm | 15mm | 40mm |

| 002-01-04 | 600 x 250 x 100mm | 15mm | 40mm |

| 002-01-05 | 750 x 250 x 100mm | 15mm | 40mm |

| 002-01-06 | 900 x 300 x 100mm | 15mm | 40mm |

| 002-01-07 | 600 x 300 x 100mm | 15mm | 40mm |

| 002-01-07 | 750 x 300 x 100mm | 15mm | 40mm |

| 002-01-08 | 900 x 300 x 110mm | 15mm | 40mm |

| 002-01-10 | 1000 x 250 x 110mm | 15mm | 40mm |

| 002-01-11 | 1000 x 300 x 110mm | 15mm | 40mm |

| 002-01-12 | 1500 x 300 x 110mm | 15mm | 40mm |

| 002-01-13 | 1500 x 300 x 110mm | 15mm | 40mm |

| 002-01-14 | 1500 x 400 x 110mm | 15mm | 40mm |

Application