Permanent Magnetic Plate Lifters

We are Manufacturer, Supplier, Exporter of Permanent Magnetic Plate Lifters and our setup is situated in Pune, Maharashtra, India.

Application

Plate Lifting Permanent Magnetic Lifter is device, required for easily

handling of plates so that laborious and time consuming work can be avoided. Conventionally chains, slings and clamps are using for lifting plates, but this method is having limitations because generally multiple plates kept in stacked hence it is difficult to engage chain hook sling / clamp in it, it has to create gap between the plates for engaging it. But this

method is totally laborious and time consuming similarly not safe.

In this circumstance "Plate Lifting Magnet" is solution for it.

Characteristics

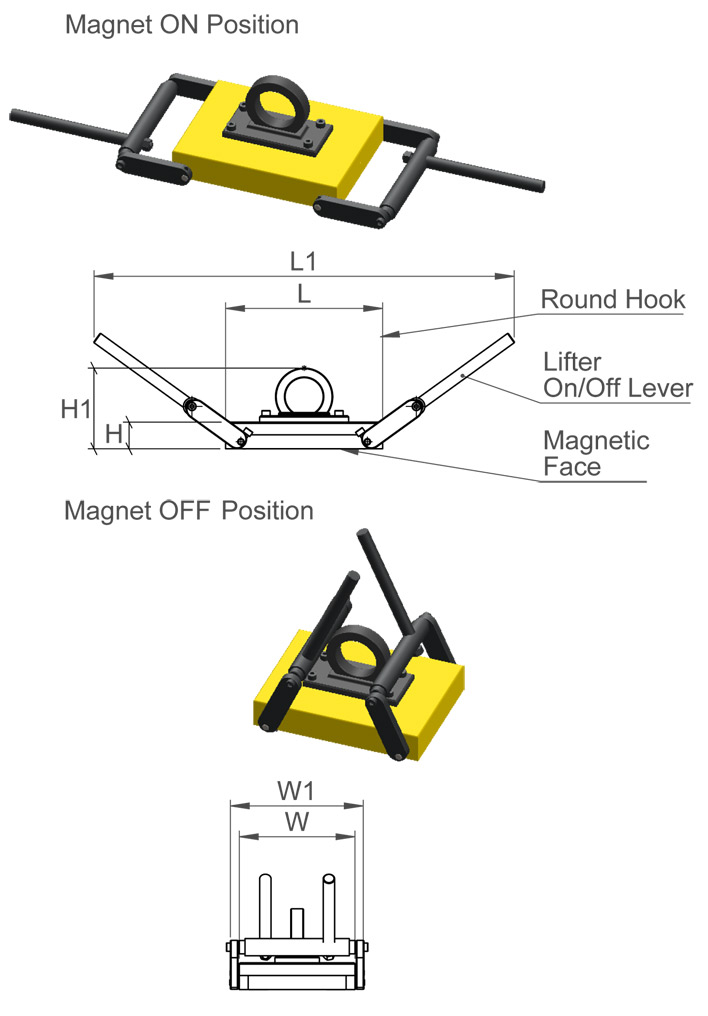

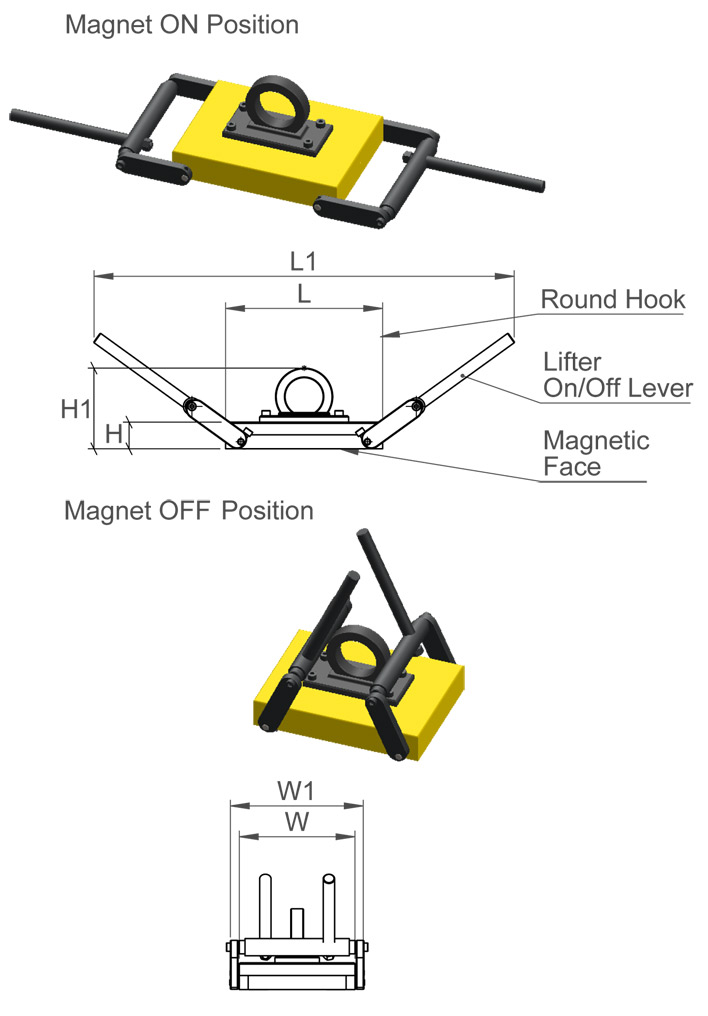

- These lifters consist of powerful Nd Fe B grade magnets it help to

reduce the self weight and increases lifting capacity of lifters.

- This special type of Permanent Magnetic Lifter is used for especially

PLATE LIFTING. This device is energized and de-energized (ON-OFF) by simply turn of TWO LEVERS (Handles). No external power supply is required for operating it.

- The effectiveness of lifting is varying due to plate size (area of plate)

hence as per plate size multiple lifters are required; see the

photographs which are self explanatory.

- M.S.Fabricated tackle is required to hangmultiple lifters for balancing of plate and avoid sag of plate; it can be design according to plate sizes.

- We provide three times factor of safety in it, which means, if lifter is

recommended for 100 Kgs weight lifting capacity it has been tested for

300 kgs lifting capacity. The 1:3 safety factor of recommended Load

Test. The Test Load ensures optimal working conditions even with

substantial operating air gaps.

Operating Instructions

- Permanent Magnetic Lifter use for any ferrous material.

- The magnetic Field controlled by ON/OFF position of the handle/ lever.

- For energize (ON) the lifter both handle rotate down direction.

- For de- energize (OFF )the lifter both handle rotate TOP direction.

- See the photograph.

Spares

All the spares like, magnetic assembly, handle, hook etc. are available

so that lifter never in scrap (unused) conditions by wants of these

spares.

Accessories

A) MS Fabricated Tackle B) Sling, Chains, ‘D’ shackle, links etc.

Precautions

- Lifter used for that application which it made.

- Do not lift weight beyond recommended lifting capacity.

- Assure contact area and balance while lifting.

- Do not try to lift very HOT jobs.

- Magnetic faces should keep clean and dent free.

- When lifter is not in use for long period apply grease OR oil on

magnetic faces it avoid to rusting of it.

- It is recommended to test load at least in a year so that it confirm the

lifting capacity and life of spares.

Safety Factors

We provide three times factor of safety in it, which means, if lifter is

recommended for 100 Kgs weight lifting capacity, it has been tested for

300 kgs lifting capacity, because practically magnetic face is not cover

100% with lifting object due to its unevenness, scaling, some coating

on the job punching some charactor or number etc. these all factors

are creating GAP between magnetic face and lifting object, hence

factor of safety should be considered.

Performance of Lifter

Consider 40% lifting force while lifting round job due to it line contact.

For 100% utilization of recommended capacity, required close contact

between magnetic face and lifting object.

Safety Related NORMS

- Lifters are checked on Universal Testing Machine (UTM) for load testing.

After testing, it certify by the Laboratory and provide the certificate.

- Considering three times factor of safety, that means if the lifter is being

recommended to lift 100kgs, this lifters should be lift 300 kgs. at least.

- NOTE: It is recommended to test load at least in a year so that it

confirm the lifting capacity and life of spares.

Operation Sequence (Follow-up the steps)

- Hang the lifter with M.S. fabricated tackle.

- Align the lifters with the plate and confirm whether the lifters are aligned

properly or not (it should be properly align)

- Turn both handle/ lever in down direction for energize (ON) it.

- Lift it for 6” height (approximate) and confirm whether it is properly lifted

or not.

- Carry it to desired place with minimum height from ground level (1 feet

height approximate).

- After reaching to desire place, it kept properly.

- Turn both handle/lever in top direction for de-energize (OFF) it.

| Code No. |

Nominal Size (Lx WxH) |

Lifting Capacity |

Self Wt. (Approx.) |

| 010-02-01 |

200 x 150 x 50 mm |

250 Kgs |

13 Kgs. |

| 010-02-02 |

300 x 200 x 50 mm |

500 Kgs |

16 Kgs. |

- Required TWO lifter for lifting plate, size L3 mtr x W1.5mtr x Thick within 8 to12mm, with weight size 250 to 450kgs.

- Required FIVE lifter for lifting plate, size L6 mtr xW2mtr xThick within 8 to 12mm, with weight size 750 to 1150kgs.

Fabricated Assy. Handling

Flat Plate Handling

Sheet Metal Handling